Debunking lack of resource in efficiency issues

A decade ago, I worked as financial controller in a glass bottle manufacture located in the south of China. Actually, the “Guele de bois” chapter of Stand(H)ard is heavily influenced by that experience. For years, the plant suffered continuous losses, which were explained by a so-called ‘lack of efficiency‘. My task was to improve the situation, or else, support management in closing the company.

To summarize, a glass manufacture is a never ending furnace. You feed sand, broken recycled glass and energy; and the furnace spits out a river of burning melted glass. Blades and moulds cut then shape glass into all kinds of bottles. Bottles continue to cool down passing through smaller ovens before inspection, sorting, packaging and finally shipment. So basically: Equipment + Sand + Oil + People = Glass bottles.

“Lack of resource”

As discussed in the Reflecting Vixen, ‘efficiency’ was the go to answer to solve and explain everything. In my first round of reviews with managers, the lack of efficiency results from another department’s mistake or lack of equipment. When investigating solutions, very few reviewed their own process or method.

My team and I of course crunched numbers and provided countless of analytical studies. We provided piles of focused and specific studies to measure the financial impacts of variations for every little details. All this to help support better decision making that could ultimately help the company reverse the trend and revert to profits. As much as I’d love to say that my work provided answers, it didn’t. Don’t get me wrong, if anyone is asking me about it, I will still vouch for financial analysis and data based decision to be the source of improvement, I mean that is after all why clients are paying me. But the reality is that improvements and ultimately efficiency came from somewhere else.

“Simple actions and innovative solutions”

Every week, new data and analysis were an excuse to meet with every managers one by one. Rather than arguing about figures, we just walked through their workshop, reviewed flows (in and out), and brainstormed potential process improvements. We listed action plans, from ‘immediately doable’ to ‘need heavy investment’. It was obviously unthinkable to do any additional investment at this point and considering accumulated losses, but a direct rebuff would have been poorly perceived. And so heavy investments items were left on the back burner, but still high in managers’ dreams. Meanwhile, we start implementing all simple and immediately doable items. The reality is that workers and managers know how to improve and be more efficient, but hardly anyone sincerely ask them. Figures are relevant to identify and rank problems, but less to provide concrete and reliable solutions.

Most actions were every basic, such as installing white boards between departments to feedback quality and adjust settings such as temperature. Some required more imagination, such as installing slides to feed raw materials into batching feeders After three months, things were already turning back up, with an improved efficiency without any new major investments nor restructuring plan. After a year, we recorded the first profitable year in a decade.

So what?

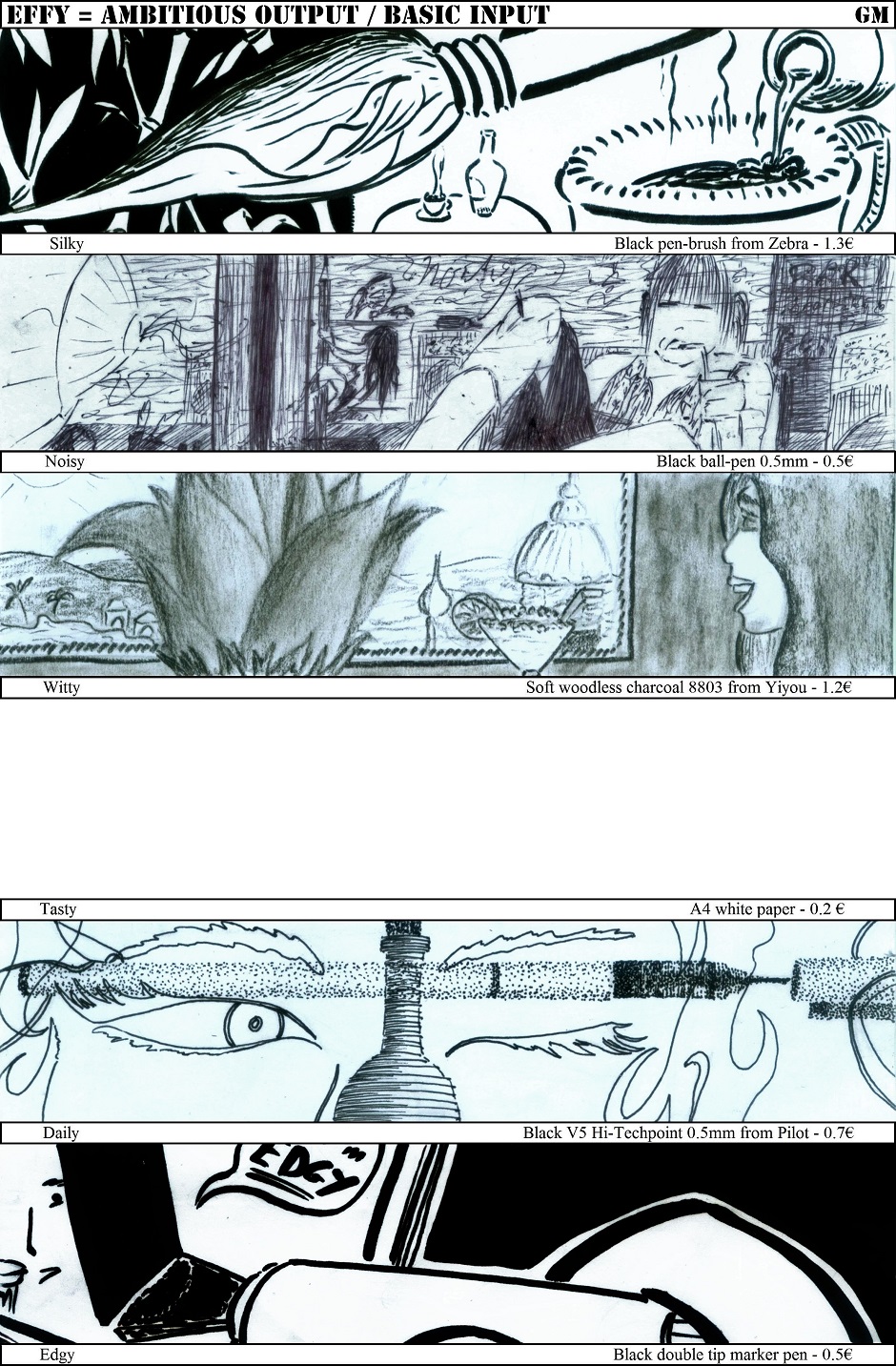

So the moral is that efficiency doesn’t need much resource. Efficiency needs ambition, basic tools, will and dedication, and so does “Effy – The Living Efficiency“.

G.M.

[…] 23 – Effy = Ambitious outputs / Basic inputs […]